Weeds. Controlled.

Getting the maximum efficacy from your herbicide is essential to ensuring a high-yielding crop. From pre-seed to post-harvest, and across crops, we have the herbicide options you need to maximize crop potential today and manage resistance for tomorrow.

As a member of CropLife Canada, UFA supports initiatives to manage herbicide resistance and assist farmers in their stewardship of the land.

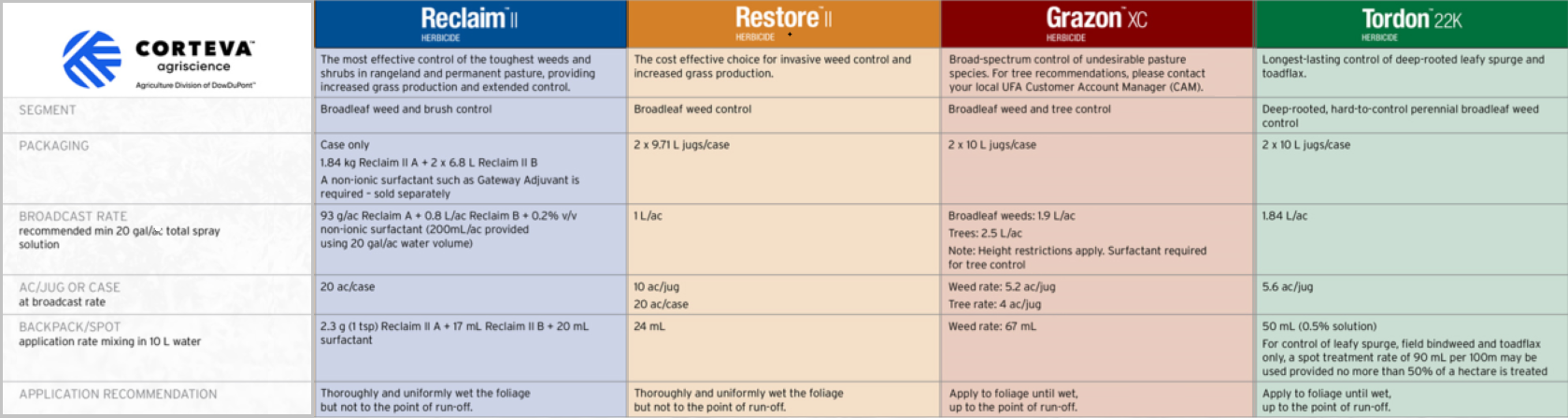

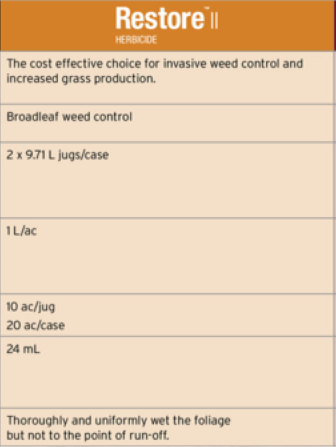

Herbicide Options

TIPS FROM THE FIELD

Starts with the Tank mix

The right order makes all the difference when tank mixing. Follow the simple W.A.L.E.S. method.

Herbicide Layering

Combining modes of action can result in a strategy with a one-two punch for your crop.

Weather Consideration

There is more than just rain to consider when choosing your weather window.

Preparing For Harvest

Figure out the factures for your pre-harvest application.

Calibrate Field Sprayer

Taking the time to ensure your sprayer is properly calibrated, even a new sprayer, saves time and money in the end.

Clean, Crop-safe Sprayer

Clean equipment means less chance of issues when growing multiple crops.

Environmental & Personal Safety

Keep the environment, yourself, and others safe while spraying.

Top 10 Resistance Weed Management Practices

Put these practices to work to get a leg up on weeds